Kit Homes

Contact us

We offer a complete, architect designed, Kit Home solution.

- Timber Frame Kit Homes and Passive Slab – Erected and Airtight within Two Weeks

We deliver award winning, flat pack Kit Home design and build services. We provide fully engineered timber frame housing solutions, from planning phase Sustainable Architects design services through to erected timber frame Kit Homes. Using Passivhaus principles our pre-assembled thermal bridge free build system can reduce heating bills by 90% and is rapid, affordable and uses sustainable materials. We can provide flat pack homes for Self Build, Social housing or commercial developments, to any design.

Why Choose Us? – Quality, Affordability, Sustainability

Phase 1 – RIBA Architects design and planning permission

Our experienced Sustainable Architects can design your kit home from scratch or developing initial ideas into working passive design. With 35+ years experience in urban planning, sustainable architecture and low carbon kit housing design, we can integrate your needs and produce stunning contemporary or traditional designs for your kit home or self build project. For examples of our past design work and timber frame kit builds see our Portfolio.

Phase 2 – Passive design and Kit Home build package

Once planning permission is secured we take architects designs and develop them into released kit homes or commercial buildings, with full structural engineering calculations for the superstructure and foundation passive slab. Our Kit Home Timber Frame and Passive slab are manufactured under precise factory conditions (MMC) in County Tipperary, Ireland.

Building in this way enables greater precision and less wastage than stick building on site, further reducing environmental impact. Equally this enables ground-works and superstructure manufacture to begin simultaneously, saving between 4 and 8 weeks on Kit Home build time.

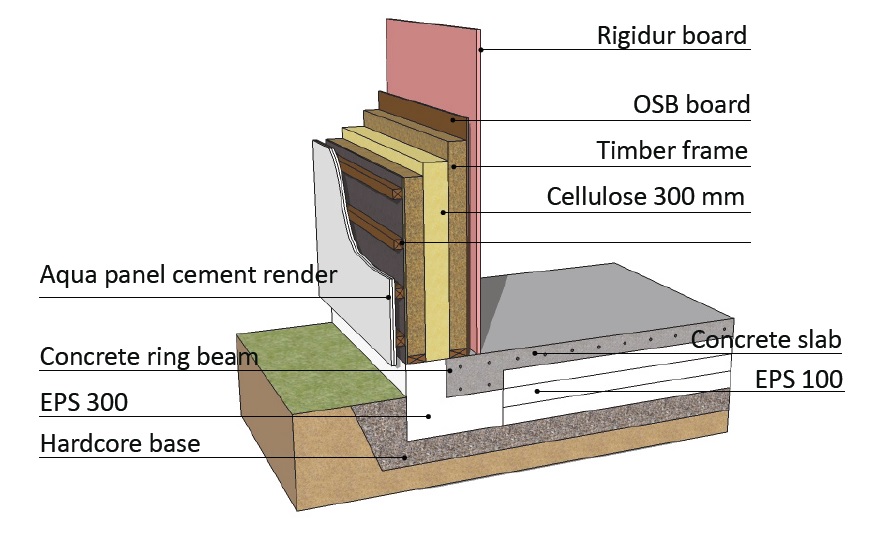

Passivhaus slab foundation – 0.10 W/m2.K u-value

Whilst the timber frame flat pack Kit Home is under manufacture, we supply and fit an engineer signed off Passivhaus certified slab foundation system, with a 0.10W/m2.K u-value and zero cold bridges. Prior to delivery of the housing kit, the client/groundworks contractor strips the site, installs the first 150mm of stone and the site roadway.

Passive Slab Foundation uses EPS 300 and Eliminates Thermal Bridging Associated with Conventioanl Build Methods

We supply and fit 50mm stone for levelling, the concrete, the steel, and the drainage pipes are brought 1 metre from the finished foundation for the mechanical contractor connect to. The Passive Slab will deliver amongst the lowest u-values on the market and eliminates the critical wall-floor cold bridge, and an essential choice when building a cold bridge free timber frame Kit Home.

Twin-Wall timber frame; cold bridge free external walls – 0.12W/m2.K u-value

The flat pack timber frame Kit Home arrives to site on low loaders, external wall closed panels are lowered in rapidly and seamlessly by crane, enabling an entire Kit Home to be watertight within a few days. Structural racking resistance is achieved by precise nailing of structurally certified wall sheeting and is covered with tear resistant breather membrane, with allowances made for overlapping at panel joints and facing joists. Timber lintels over windows and doors opening therefore allowing precise load distribution.

Metal Webbing Joist Reduce Sound Transmission and Enable Services and Ventilation to be Easily Installed

Kit Home roof structure- 0.10W/m2.K u-value: cold bridge free

Trusses Our Kit Home engineered roof truss utilises a tooth plate system, hydraulically pressed into machine stress graded European whitewood, ensuring structural integrity. The roof can be rapidly assembled from a flat pack and thermal bridging is minimised by the use of I-Beams and thermally broken detailing.

Insulation We use Warmcell cellulose insulation – made from recycled newspaper, this highly sustainable material is pumped into the Kit Home voids, filling every nook and cranny. External walls at Passivhaus specification are filled with 300mm of continuous pressure pumped high density Warmcell cellulose insulation delivering a u-value of 0.12W/m.K. Roof is pumped with 400mm of continuous pressure pumped high density cellulose insulation delivering a u-value of 0.10W/m.K.

Passivhaus Airtightness is achieved through the OSB layer, in conjunction with Intelligent Membranes and Lifetime Garunteed Tapes and Adhesives

Airtightness testing and Materials- achieving below 0.6ACH@50Pa

We supply and fit all airtightness membrane and tapes around windows and service cavity. We guarantee Passivhaus performance airtightness test below 0.6ACH@50Pa. External walls Intello membrane or OSB taped with SIGA tape with 45mm service cavity First floor ceiling intello membrane or OSB taped with SIGA tape with service cavity.

Kit Home envelope complete – ready for internal and external finishes within 2-3 weeks

Building is air and water tight with insulation and windows installed within 3 weeks of start on site